Defense is the process of removing water from soil or mud, reducing volume, improving materials or preparing a place for construction or industrial activities. It plays an important role in construction, mining, treatment of wastewater, agriculture and other fields where water management is important.

Depreciation tools refer to devices designed to separate water from solids effectively. This manual provides a detailed description of how these systems work, different types are available, and how to choose the right solution for your operating requirements.

Benefits of Using Dewatering Equipment

1. Professional Water Removal enables rapid drying and transport of mud, reducing handling time and related costs.

2. Safety and Stability in construction and mining prevents the removal of excess water, controls soil volatility, and supports a safe work environment.

3. Environmental Compliance helps companies fulfill regulations by reducing the amount of wastewater before disposal or treatment.

4. Cost Reduction is achieved as low water content means lighter transport weight and reduced processing requirements.

5. Resource Recovery allows clean water to be reused in some cases, while solids can be rebuilt or sold.

Limitations to Conside

Capital investments: Tools such as centrifuge or filter press can be expensive.

Maintenance is required: Moving parts and filters require regular inspection and maintenance.

Room requirements: Larger systems require sufficient footprint and infrastructure.

Energy consumption: Some machines, especially mechanical systems, use important power.

Not all: Efficiency material type, volume and place of place depends.

| Equipment Type | Description | Ideal Use Case |

|---|---|---|

| Centrifuges | Uses rotational force to separate water from solids | Municipal sludge, food processing |

| Belt Filter Presses | Uses belts and rollers to press water out | Paper industry, mining |

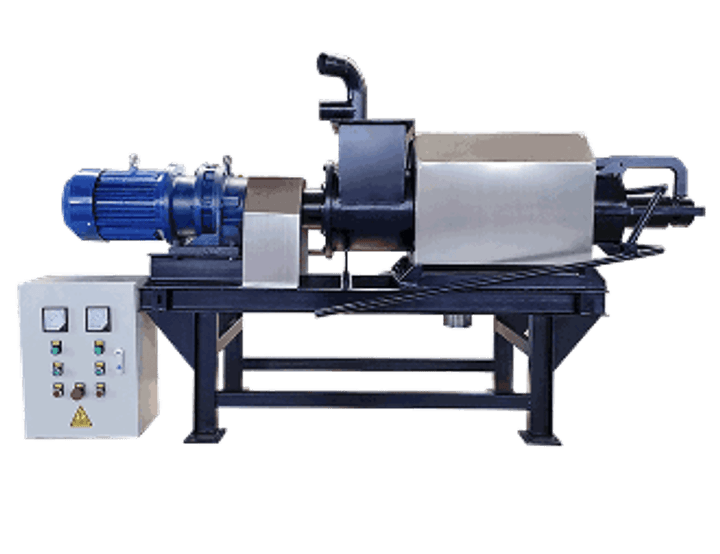

| Screw Presses | Continuous, low-speed compression | Industrial sludge, wastewater plants |

| Geotextile Bags | Large fabric containers that passively drain water | Dredging, agriculture |

| Vacuum Filters | Uses suction pressure to remove water | Chemical processing |

| Drying Beds | Sand and gravel layers used for passive drying | Low-volume sites with time flexibility |

| Submersible Pumps | Removes standing water from pits or trenches | Construction, excavation |

| Wellpoint Systems | Network of small wells and pumps to lower water table | Foundations, deep excavations |

Latest Trends and Innovations

1. Mobile Dioveling devices skid-mounted or contained systems allow on-site treatment, especially useful for external or temporary projects.

2. Smart monitoring the IoT sensor and SCADA system now enable distance monitoring of Ocing efficiency and flow rates.

3. Polymer adaptation advanced polymer injection technology improves solid length separation with low chemical use.

4. Hybrid system mixing mechanical and passive systems (e.g., screw press + geobag) to reduce energy consumption and maximize the results.

5. Mud-to-energy technologies some functions now make the waste a resource, which transforms waste into a resource.

Key Features to Consider When Choosing Equipment

Solid content high solids require other handling other than thin mud. Match the equipment accordingly.

Capacity and flow speed make sure the system handles the daily volume without bottlenecks.

Automation level from the entire manual to the smart system – select on the basis of accessibility and budget for labor.

Material compatibility check chemical and physical compatibility with the waste or soil type.

Footprint and portability think about the lack of place and need mobile or stable devices.

Maintenance frequency consider the cleaning cycle, partial change and general shutdown requirements.

Power the available electrical or fuel infrastructure can limit your equipment options.

Top Dewatering Equipment Manufacturers and Solutions

| Company | Product Focus | Region |

|---|---|---|

| Alfa Laval | Centrifuges, decanters | Global |

| ANDRITZ | Belt presses, screw presses | Europe, North America |

| Huber Technology | Wastewater sludge handling | Global |

| Evoqua Water Technologies | Industrial water systems | North America |

| Flo Trend | Dewatering boxes, geotextile containers | USA |

| Schwing Bioset | Screw presses, class A biosolids systems | USA |

| Komline-Sanderson | Vacuum filters, belt presses | Global |

| Aquatech Dewatering | Pumps, wellpoint systems | Canada, USA |

How to Choose the Right Dewatering Equipment

Checklist for Evaluation :-

What is the fixed-to-round relationship between your content?

What daily capacity do you need?

Is space a barrier on your site?

Will the equipment be used temporarily or permanently?

Do you need automation or is the manual operation enough?

Are there priorities reuse of energy and water for operation?

What regulatory compliance does your area need?

Tips for Best Use and Maintenance

1. Pilott test before investing, run a pilot test with different techniques to determine the best performance.

2. Pre-Treat Sludge When Needed use polymer additives or mechanical movement to improve separation efficiency.

3. Clean and inspect regularly plan a shutdown for maintenance to avoid collapse and maintain performance.

4. Monitoring quality test the amount of moisture in solids and the clarity of the printed water in fine-tuning settings.

5. Train operator make sure the on-site teams are familiar with the operating manual and safety processes.

6. Consider life cycle cost go beyond the starting costs – factor in maintenance, electricity, chemical use and resale value.

FAQs: Real-World Questions Answered

Q1: Which industries use the most equipment?

General areas include construction, mining, municipal wastewater, mass and paper, food processing and chemical construction.

Q2: Is dewatering necessary for all construction sites? Q3: How much moisture remains after dewatering? Q4: Can device tools be rented instead of buying?

If the groundwater table is high or the soil is saturated, Oceing is necessary for foundation and excavation work.

Depending on the method, solids can maintain 20–60% moisture. Centrifuse and pressure usually achieve dried results.

Yes, many service providers offer short and long rent for special construction projects.

Conclusion: A Practical Takeaway

Defense equipment is a spine technology in industries that manage mud, water or unstable ground. With many types and configurations available, it depends on the correct system on physical properties, the conditions of the site and the regulatory requirements.

By understanding the principles of work, professionals and opposition and maintenance practices, you can ensure better operating efficiency, environmental compliance and long-term savings.

Whether you go out to a workplace, manage mud in a treatment plant or require reducing waste costs, a well -chosen diaphegling system will have an average impact.